Manindi Battery Minerals/Metals Project, WA (MLS 80%)

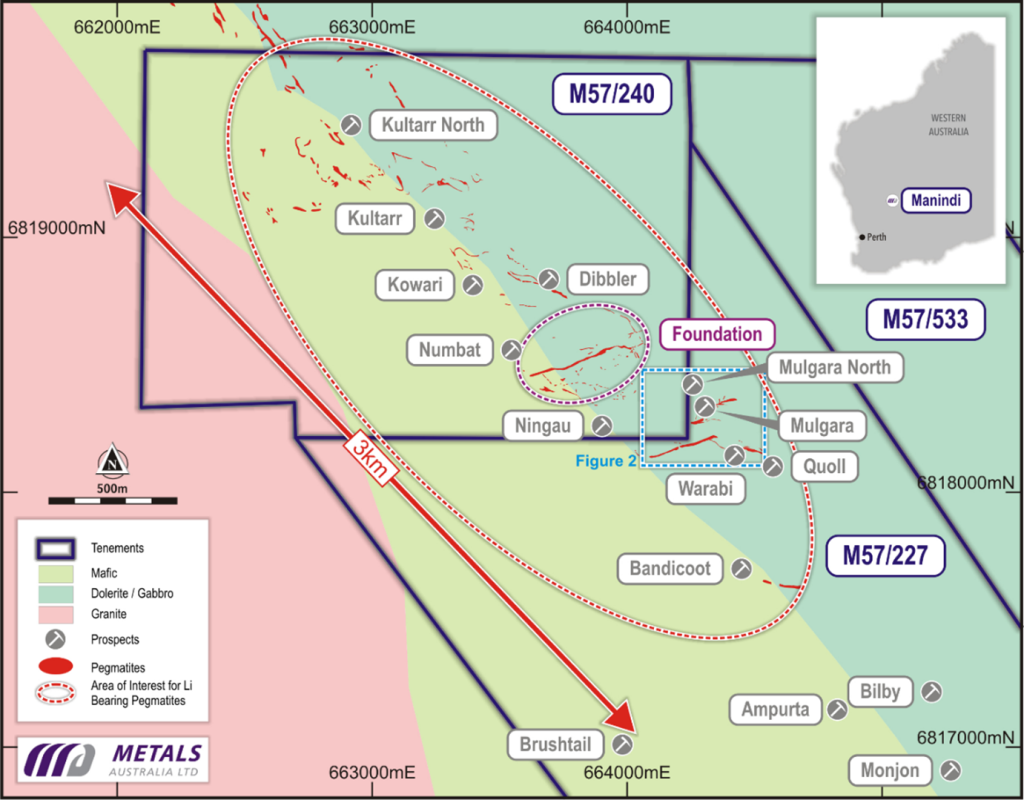

The Manindi Battery Minerals/Metals Project includes three granted Mining Leases (MLs) and is located approximately 20 km southwest of the Youanmi Gold Mine in the Murchison District approximately 500km northeast of Perth in Western Australia (see location, Figure 1, below).

The project has an existing high-grade zinc with copper resource. The Company has also been drilling and defining the project’s high-grade lithium pegmatite potential and has initiated a metallurgical lithium-concentrate program on bulk samples from recent diamond drilling. The Company has also identified an intrusive related vanadium-titanium with Ni-Cu-Co sulphides discovery.

Manindi Lithium Project

The Company has identified a corridor of lithium-bearing pegmatite occurrences over a three kilometres strike length at the northwestern end of its Manindi Project (see Figure 1 below).

Figure 1: Manindi lithium project, mapped pegmatites with rockchip and drillhole locations

Detailed surface mapping carried out at Mulgara and Warabi, situated approximately 1.3km SE of the Kultarr and Kowari zinc resources (Figure 1), previously identified at least three lithium bearing pegmatites outcropping at surface with strike lengths of over 300m and widths of up to 25-30m.

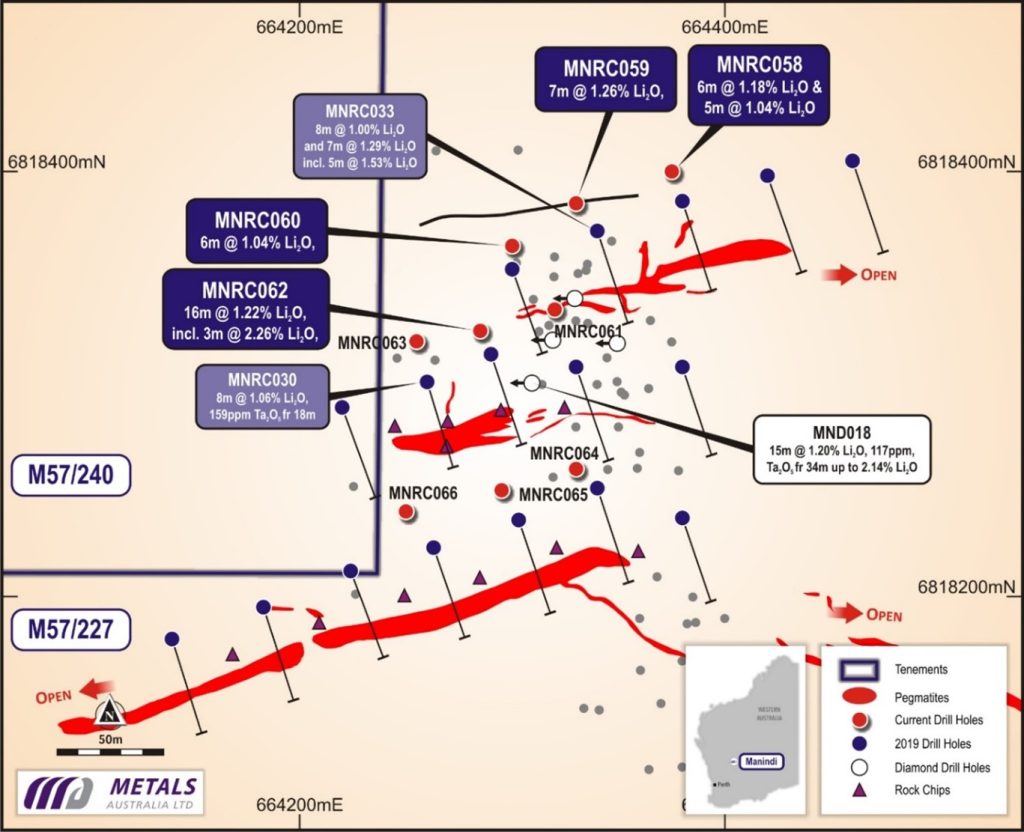

Re-sampling of previous diamond drillcore that targeted sulphide zinc mineralisation at Mulgara, produced intersections including: 15m @ 1.20% Li2O from 34m, including 5m @ 1.53% Li2O from 38m in MND018. Following the positive identification of lithium-caesium-tantalum (LCT) pegmatites at Manindi, a shallow RC percussion drilling program was completed in 2018 at the Mulgara Prospect to test the three outcropping pegmatite dykes identified (see Figure 2 below).

Significant intersections produced from this RC drilling program at Mulgara included: 8m @ 1.06% Li2O from 18m incl. 3m @ 1.65% Li2O with up to 1.96% Li2O in MNRC030.

Figure 2: Mulgara LCT pegmatites with rockchip and recent/previous drill hole locations

Preliminary flotation tests on previous diamond drilling samples produced concentrates with grades up to 3.05% Li2O and lithium recovery of up to 77% from a concentrated 30% of the mass feed. Flotation tails contained significant tantalite mineralisation (Ta2O5) that could also be recovered and provide additional upside to the potential economics of the project.

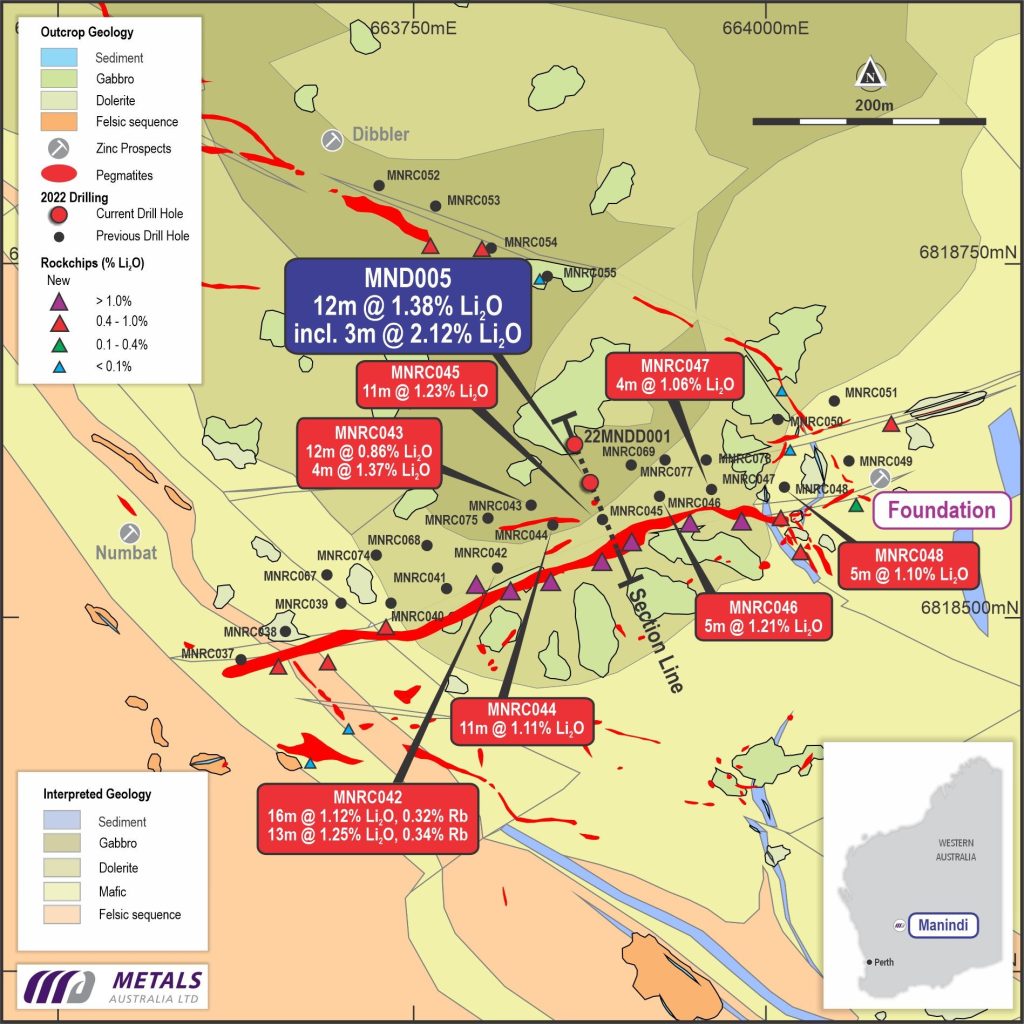

Further mapping and systematic rockchip sampling in late 2021 resulted in the discovery of the Foundation Pegmatite (Figure 1 and 3 below), which is the largest pegmatite identified to date at Manindi. The Foundation Pegmatite has a 500m strike-length, trending in a southwest–northeast direction, and includes multiple pegmatite outcrops across a 200m wide zone in a northwest-southeast direction (see Figures 1 and 3).

Rockchip sample results averaging >1% Li2O with Cs, Ta and >0.4% Rb and up to 2.30% Li2O and 0.70% Rb, confirm that Foundation is a high-grade LCT pegmatite (Figure 3). These results compare favourably with previous results from rockchip sampling of the Mulgara pegmatites that produced high-grade results of up to 2.84% Li2O, 296 ppm Ta205 and up to 746ppm Cs2O.

During 2022 the Company recently completed a 44 hole, 3,500m, RC drilling program that tested the Foundation and Mulgara Pegmatites (Figures 1 and 3) as well as other nearby zones (e.g., Dibbler, Quoll and Bandicoot. Thick and high-grade lithium-rubidium intersections have been produced from the Foundation and Mulgara pegmatites, including:

- Foundation: 16m @ 1.12% Li2O, 0.32% Rb incl. 13.0m @ 1.25% Li2O, 0.34% Rb in MNRC042

- Mulgara: 11m @ 1.23% Li2O, 0.31% Rb incl. 5m @ 1.47% Li2O, 0.30% Rb in MNRC062

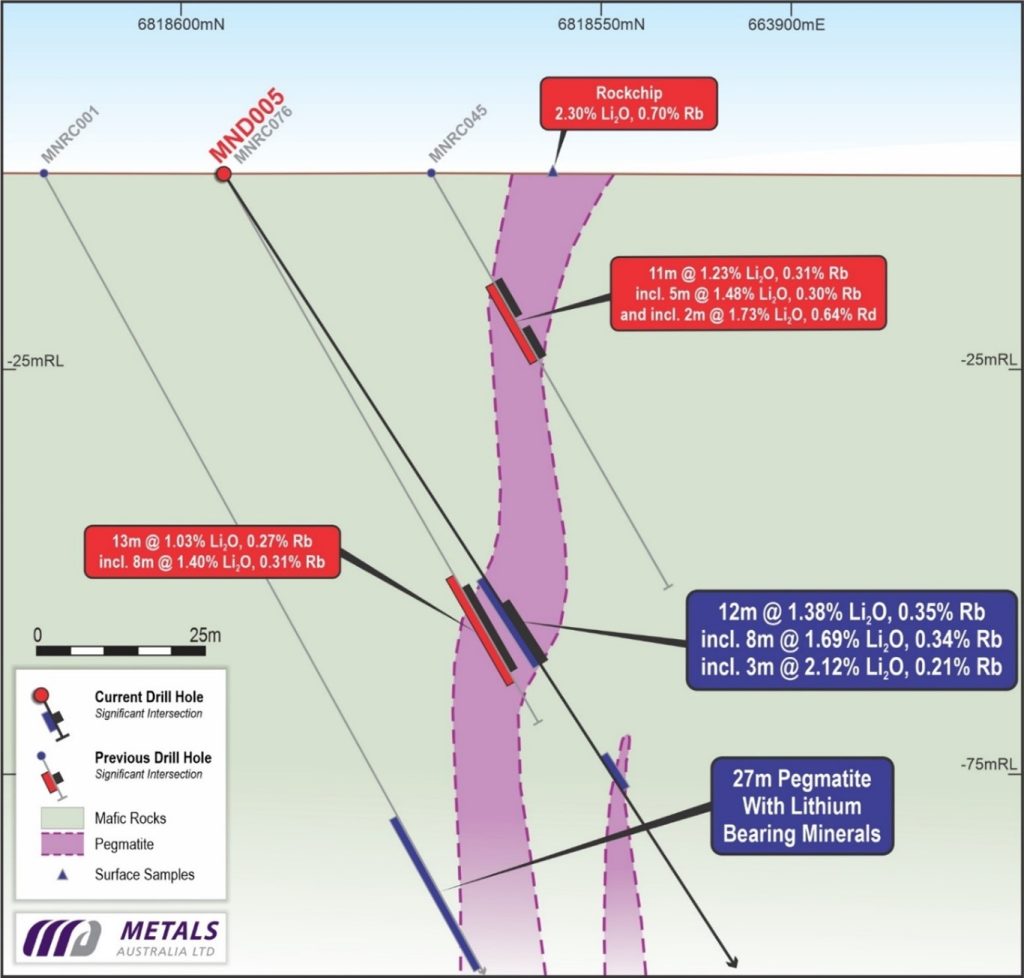

During early 2023 the Company announced a high-grade lithium pegmatite diamond drilling intersection from the Foundation Pegmatite (see Figure 4). The diamond hole intersected a 12.5m approximately true-width zone of steeply dipping pegmatite with visible lepidolite and petalite crystals throughout, producing a 12m intersection grading 1.38% Li2O including 3m @ 2.12% Li2O.

Figure 3: Manindi Project, Foundation Pegmatite, drilling and rockchip results

The high-grade lithium-bearing pegmatite at Foundation has been drilled to more than 120m below surface and remains open at depth (see cross section, Figure 4 below).

Figure 4: Cross section through diamond hole MND005 which tested the high-grade Foundation Pegmatite

Previous rock chip sampling of this high-grade pegmatite discovery produced results averaging over 1% Li2O along the entire 500m strike length of the identified pegmatite zone (see Figure 3). This was confirmed by RC drilling, which tested the Foundation Pegmatite as part of the 3,500m RC drilling program in 2022, producing widespread lithium intersections within a 3km x 1km NW-SE trending pegmatite corridor.

A metallurgical testwork program has been initiated at Manindi, based on a more than 40kg drill-core bulk sample from MND005 grading 1.33% Li2O. The testwork, to be carried out at Nagrom laboratories in Perth and managed by CPC Engineering, will initially examine potential to produce a lepidolite-petalite concentrate targeting 3-5% lithium grade. The Company is in discussions with potential off-takers for such a concentrate.

A second stage of metallurgical testwork will examine potential for down-stream processing to leach the lepidolite and petalite (and/or converted spodumene) concentrate then precipitate high-value lithium carbonate as well as other in-demand products such as rubidium, cesium and tantalum.

Subject to positive results from the metallurgical testwork and offtake discussions, a Mineral Resource delineation drilling program will be carried out as well as preliminary economic development studies.

Manindi Zinc-Copper-Silver Resources

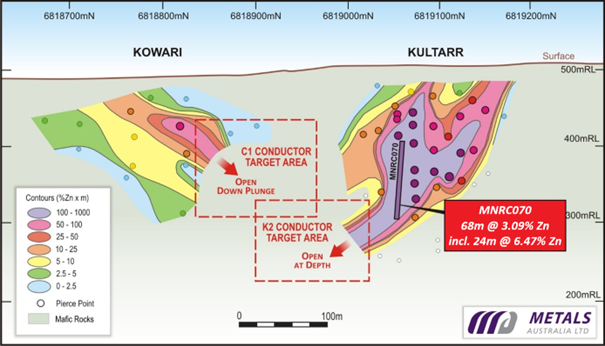

The Manindi Base-Metals Project includes the high-grade Kultarr and Kowari Zinc deposits (Figure 1), located close to the northern end of the Project at the boundary between a sequence of mafic intrusive units and mafic volcanics and felsics to the west.

These deposits host a JORC 2012, Measured, Indicated & Inferred Mineral Resource of 1.08Mt @ 6.52% Zn, 0.26% Cu, 3.2g/t Ag for 70,102t Zn (2% Zn cut-off) (including a Measured: 37.7kt @ 10.22% Zn, 0.39% Cu, 6.2g/t Ag; Indicated: 131.5kt @ 7.84% Zn, 0.32% Cu, 4.6g/t Ag and Inferred: 906.7kt @ 6.17% Zn, 0.25% Cu, 2.9g/t Ag).

In 2022 the Company produced an exceptional zinc with copper and silver intersection at the Kultarr Zinc Prospect (see location, Figure 1):

- 68m @ 3.09% Zn (0.20% Cu, 2.33 g/t Ag) from 89m (down hole) in MNRC070, including 24.0m @ 6.47% Zn (0.29% Cu, 3.58 g/t Ag) from 100m.

The intersection in MNRC070 has extended the high-grade zinc mineralisation at Kultarr down plunge to the south (see longitudinal projection, Figure 5).

Previous electromagnetic (EM) surveys show EM anomalies at depth below both the Kultarr (K2 anomaly) and Kowari (C1 anomaly) zones (Figure 5). The high-grade intersection in MNRC070 confirmed that the high-grade zinc mineralisation extends beyond the previous drilling and opened-up potential to significantly expand the high-grade zinc resources at the prospect.

Figure 5: Manindi Zinc Project. Kultarr and Kowari Longitudinal Projection with MNRC070 Intersection

Manindi West Vanadium – Titanium (Ni, Cu, Co) Discovery

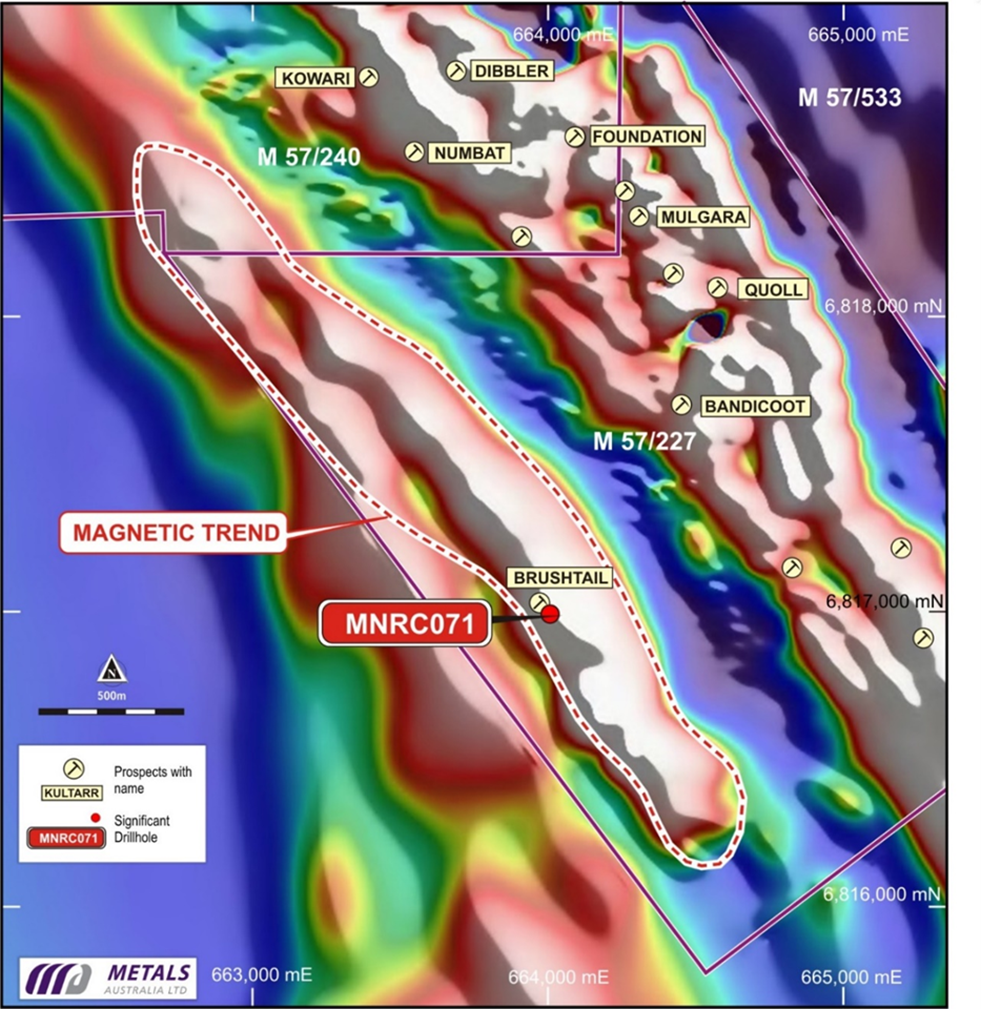

In 2022 the Company announced a significant vanadium (iron, titanium) intersection with zones of nickel-copper-cobalt sulphide mineralisation from MNRC071. This was the first drillhole that has tested the Manindi West/Brushtail target5 (see Figure 5 below).

This RC drill hole tested an EM anomaly associated with a major northwest trending magnetic zone of more than 3 kilometre (km) strike length and 1 km wide, located to the southwest and parallel to the corridor that contains the Kowari and Kultarr zinc resources (see Figures 1 and 5).

Figure 6: Total magnetic intensity image showing Manindi West magnetic unit and MNRC071 location

MNRC071 passed through a zone of felsics and pegmatite and oxidised material before intersecting a fresh, magnetic mafic intrusive unit from 48m downhole and continued in this unit, interspersed with pegmatite dykes, for the entire length of the hole to 130m depth.

High vanadium, iron and titanium values in the mafic intrusive produced an overall intersection of 82m @ 0.30% V2O5, 27.5% Fe and 11.5% TiO2 from 48m downhole that included 70m @ 0.32% V2O5, 29% Fe, 12.2% TiO2, 0.02% Ni, 0.03% Cu, 159ppm Co from 48m including 27m @ 0.35% V2O5, 35% Fe, 14.8% TiO2, 0.03% Ni, 0.05% Cu, 221ppm Co.

This zone also included sulphide mineralisation that produced significant nickel, copper and cobalt results including: 6m @ 0.08% Ni, 0.11% Cu, 506ppm Co (0.32% V2O5, 39.3% Fe, 21.9% TiO2) from 59m & incl. 2m @ 0.13% Ni, 0.08% Cu, 779ppm Co (0.21% V2O5, 36.2% Fe, 15.6% TiO2) from 59m.

The high iron, titanium and vanadium levels throughout the mafic intrusive intersected by MNRC071 are associated with magnetite rich zones interpreted to be associated with the lower layers of the western Youanmi mafic-ultramafic Complex. There is also potential for higher-grade massive sulphide accumulations at the base of the intrusive.

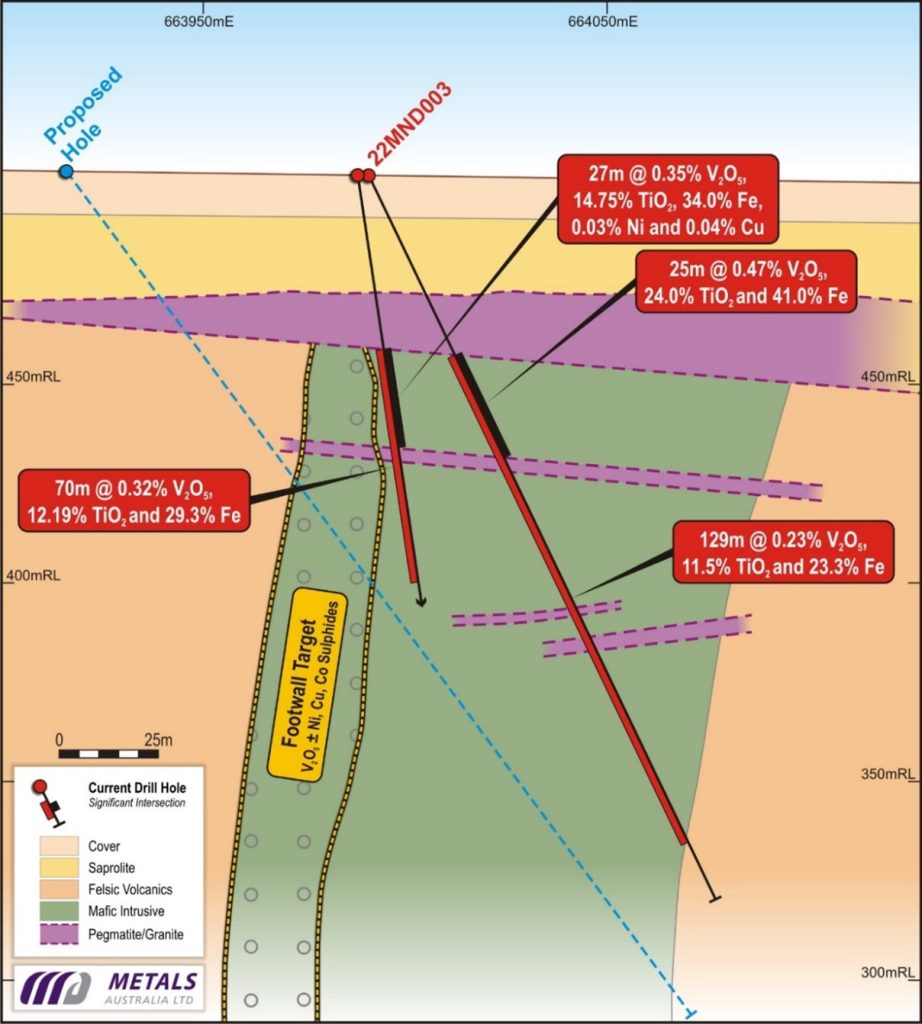

Subsequently diamond drillhole MND003 tested the 3km strike length Manindi West mafic intrusive target below previous RC hole MNRC071 that produced a broad vanadium titanium intersection of 70m @ 0.30% V2O5, 28% Fe, 11.5% TiO2 from 48m incl. 20m @ 0.44% V2O5, 34.8% Fe, 14.3% Ti2.

The new diamond drill hole (MND003) produced a broad intersection of 129m @ 0.23% V2O5, 23.3% Fe and 11.5% TiO2 from 53m downhole to the eastern or hanging wall contact of the intrusion. It included a high-grade intersection on the western side of the intrusion, east of the interpreted footwall contact (that remains untested) of 25m @ 0.47% V2O5, 24.0% TiO2 and 40.8% Fe, from 53m.

Figure 3: Cross Section through MND003 intersection, Manindi West with previous MNRC071 intersection

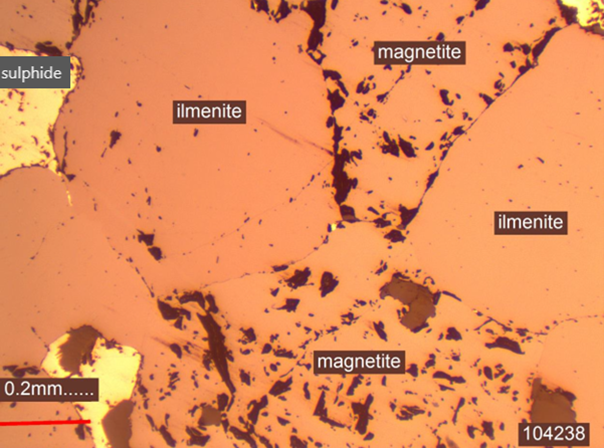

The high grades of titanium including intersections up to 24% TiO2 indicates that the titanium may be contained in ilmenite that may be separated as a titanium ore, separation of which would in-turn upgrade the vanadium content in the remaining magnetite concentrate. Mineralogical work

Petrography results on the high-grade titanium vanadium-iron and nickel-copper-cobalt bearing sulphide mineralisation from drillhole MND003. The petrography shows that the titanium is contained in coarse-grained ilmenite, distinctly separate from the coarse magnetite grains that contain the vanadium (see Image 1 below).

Scanning Electron Microscope (SEM) analyses of the magnetite and ilmenite confirmed that:

- Titanium is almost entirely contained in the ilmenite (SEM: TiO25%, FeO 46.5%, V2O5 0.3%), and,

- Vanadium is almost entirely contained in the magnetite (SEM: V2O56%, FeO 97.7%, TiO2 0.35%).

Ilmenite is a composite of iron and titanium oxides and is weakly magnetic. Highly magnetic minerals, such as magnetite, can be separated by a low intensity magnetic separator to produce a high-grade magnetite concentrate of up to 60% Fe and >1% V2O5 that would potentially represent a high-grade product for downstream processing to produce high-value vanadium-pentoxide for Vanadium Redox Flow Batteries (VRFBs) for renewable energy storage.

The residual material can then be subjected to a wet high intensity magnetic separation stage to concentrate the ilmenite. The resulting high-grade titanium ilmenite concentrate (targeting >50% TiO2, >25% Fe) would represent an additional high-value titanium-iron product. It would also be possible to produce a Ni-Cu-Co bearing sulphide concentrate as a final stage.

Metallurgical testwork on diamond drillcore is now being initiated to carry out this testwork program.

Image 2: MND003, 66.3m, magnetite – Ilmenite cumulate with interstitial sulphides