Manindi Critical Minerals Project, WA (MLS 80%)

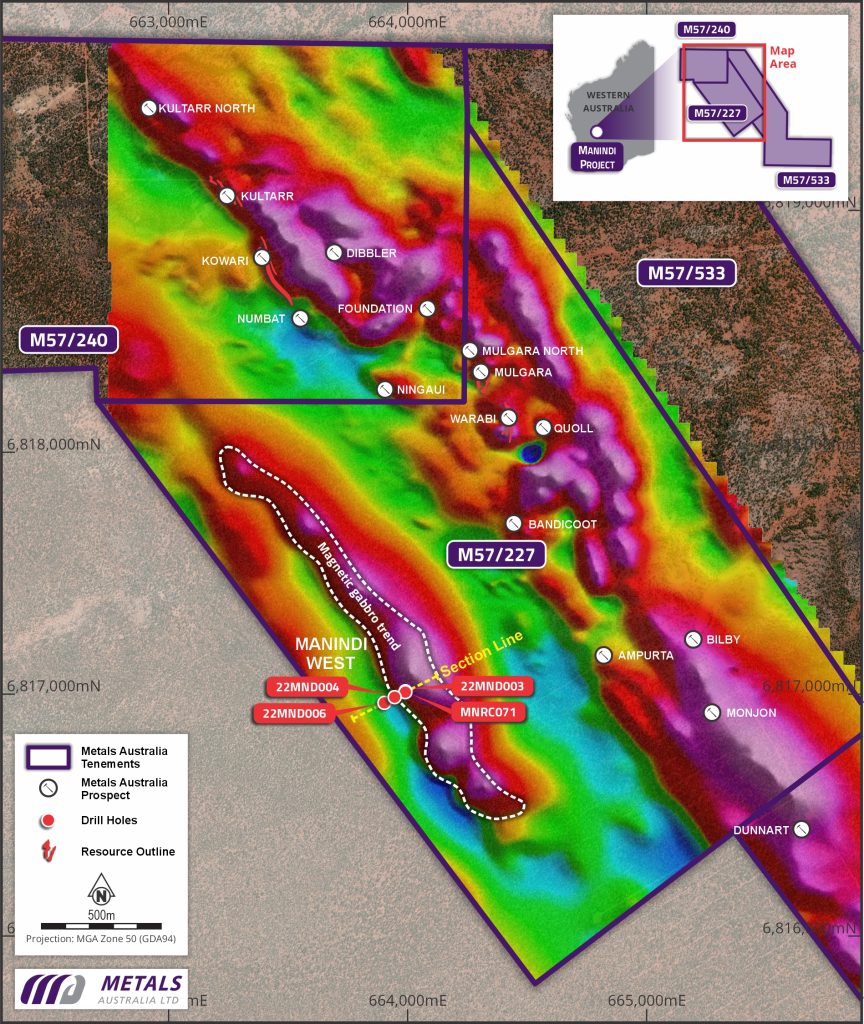

The Manindi Project includes three granted Mining Leases (MLs) and is located approximately 20 km southwest of the Youanmi Gold Mine in the Murchison District approximately 500km northeast of Perth in Western Australia (see location, Figure 1, below).

- Manindi Zinc-Copper-Silver Resources: high-grade zinc with copper project with existing Mineral Resource – 1.08MT at 6.52% Zn, 0.26% Cu, 3.19 g/t Ag.

- Manindi Titanium-Vanadium-Iron Discovery: The Company has discovered a high-grade titanium-vanadium-iron prospect in close proximity to the zinc-copper-silver resource outlined above.

- Manindi Lithium Project: The Company has previously drilled and defined a lithium pegmatite prospect with completion of an initial metallurgical testwork program.

Manindi Zinc-Copper-Silver Resources

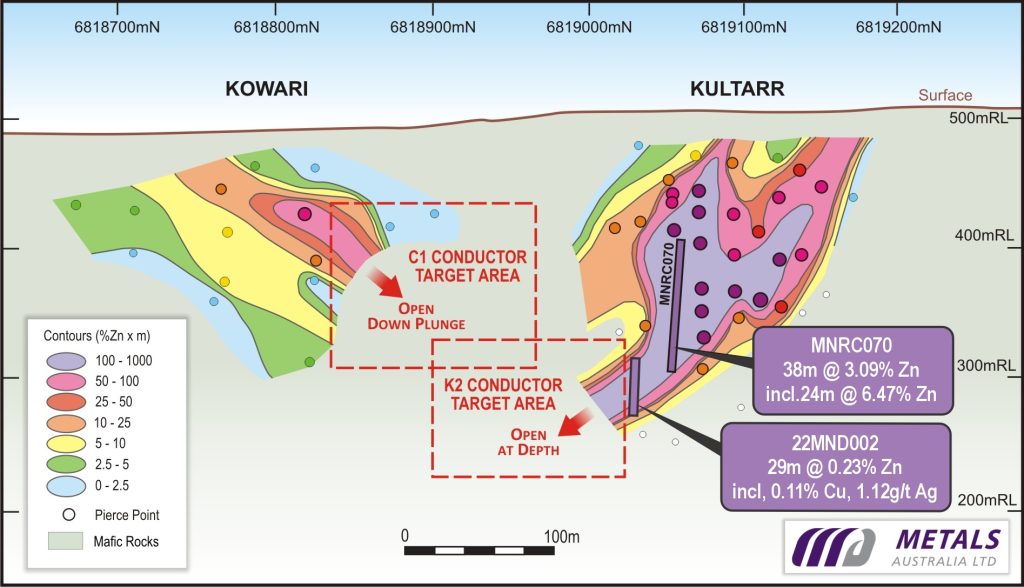

Metals Australia’s Zinc-Copper-Silver project contains a Mineral Resource of 1.08 Mt at 6.52% Zinc, 0.26% Copper and 3.19 g/t Silver (including Measured of 37,697 tonnes @ 10.22% Zn, 0.39% Cu, 6.24 g/t Ag, indicated of 131,472 tonnes @ 7.84% Zn, 0.32% Cu, 4.6 g/t Ag & Inferred of 906,690 tonnes @ 6.17% Zn, 0.25% Cu & 2.86 g/t Ag). The project had largely been on hold following the rapid pull back in Zinc prices that occurred during the first half of 2022.

In late 2024, the company commenced a revaluation of the project, given its proximity to the high-grade Titanium-Vanadium-Iron project and trends in metal prices for zinc, copper and silver. While uncertainty still exists regarding the near-term outlook for zinc, recent price movements have resulted in a significant lift to the mineral value of the resource.

As a result, a comprehensive review of all available information related to the project – including the existing JORC Mineral Resource and potential extensions was commenced – and will continue in 2025.

The key aim of the review is to refine resource extension targets that can be drilled to support an increase in the current Mineral Resource. Previously completed and reported down hole electromagnetic work (DHEM) has identified drill targets at depth including those between the known Kultarr and Kowari Resources (Figure 1).

The current Mineral Resource lies within 2 kilometres of the high-grade Ti-V-Fe project outlined in the section below. The ability to grow both projects in parallel also presents an opportunity for a potential combination project, where synergies for potential operations and processing can be further explored in a potential future scoping study. Alternative synergy opportunities within the broader region will also be investigated to determine the best way for value to be created for both the existing Zn-Cu-Ag resource and the high-grade Ti-V-Fe prospect.

Figure 1: Manindi Project Overview, Regional Magnetics, Resource Locations (red) & Ti-V-Fe discovery

Figure 2: Manindi Zinc Project. Kultarr and Kowari Longitudinal Projection with MNRC070 Intersection

Manindi West Vanadium – Titanium (Ni, Cu, Co) Discovery

The Manindi West Ti-V-Fe Project has previously been identified within a 3 km long magnetic trend. (Figure 1 & 2)

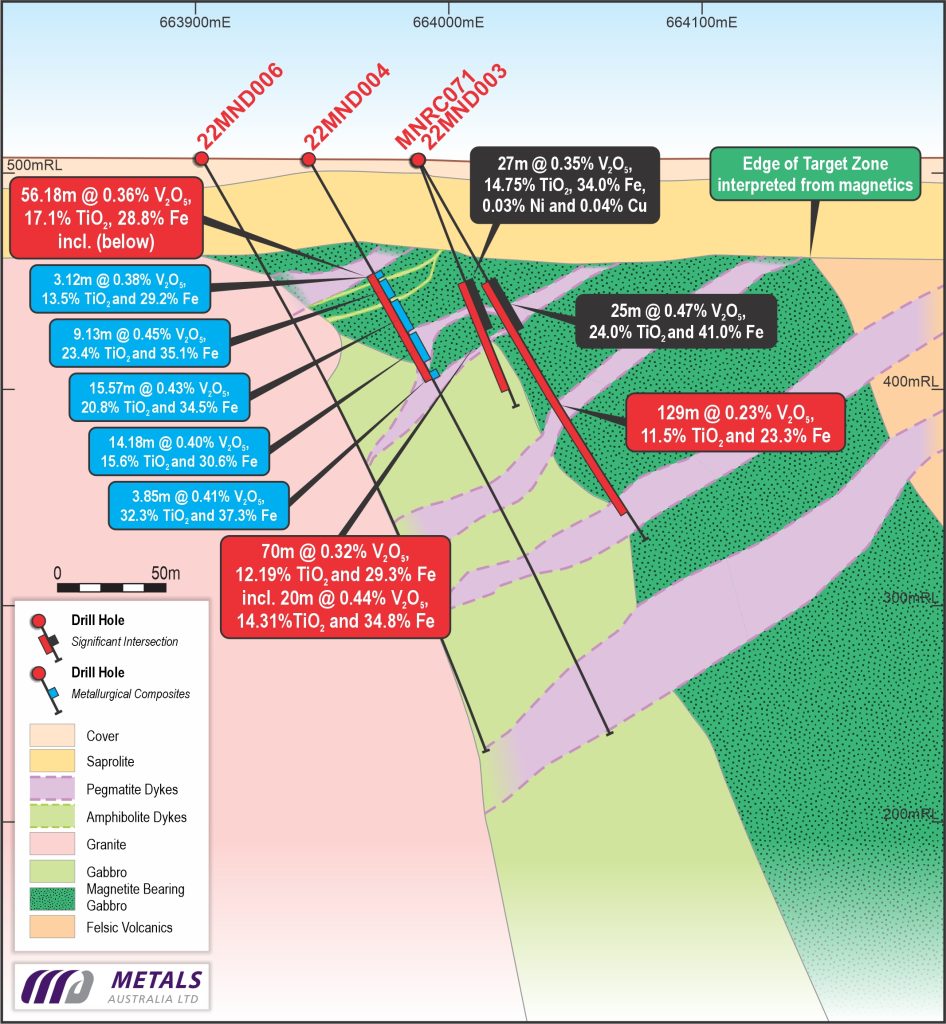

Prior drilling by the company included RC hole MNRC071 that produced a broad vanadium-titanium-magnetite intersection of 70m @ 0.30% V2O5, 28% Fe, 11.5% TiO2 from 48m including 20m @ 0.44% V2O5, 34.8% Fe, 14.3% TiO2 from 80m and 22MND003 which produced a broad intersection of 129m @ 0.23% V2O5, 23.3% Fe and 11.5% TiO2 from 53m downhole. The position of other drill hole locations is also shown (Refer to Figure 3).

In late 2024, work focused on identifying and sourcing representative core sample to progress the planned metallurgical test work aimed at preparing and evaluating typical concentrate characteristics that can be obtained from the ore. Hole 22MND004 was selected for this purpose. The hole had intersected a broad zone of titanium and vanadium mineralisation cut by several narrow biotitic amphibolite dykes and a series of broader pegmatitic and aplitic dykes that are locally rubidium bearing with lesser lithium, bearing micas.

A composite sample from 22MND004 was prepared and sent to the laboratory, with test work scheduled and underway. The composite sample was taken from the drilling intercept of 58.18m @ 0.36% V205, 23.4% TiO2 and 28.8% Fe from 60.55m downhole, incorporating an aggregate intersection of 45.85m @ 20.2%, TiO2 (12.1% Ti), 0.42% V2O5 & 33.3 % Fe. Figure 3 shows hole 22MND004’s position and the five intervals composited from within the magnetite bearing gabbro target zone.

The main aim of the test program is to determine whether the concentrating process can economically generate separate concentrate streams of commercial grade. The test work will investigate whether a high-grade magnetite concentrate grade targeting ~ 60% Fe and > 1% V2O5 can be obtained. The test work will also separately seek to produce high-grade titanium / ilmenite concentrate targeting > 50% TiO2 & >25% Fe. Both concentrates, subject to impurity levels (calcium, magnesium, phosphorous, silica etc.), will then be assessed for their suitability for further downstream processing.

Given the significant magnetic intensity variation between Ilmenite (low) and magnetite (high), a test program has been developed to separate and concentrate the two products. The test program will involve crushing, grinding and stages of Low Intensity Magnetic Separation (LIMS) to separate streams ahead of Wet High Intensity (WHIMS) Magnetic Separation to further refine the concentrate.

The technical and the commercial merit of the concentrate streams will shape next steps for the project, including assessing further drilling to define tonnage and grade within the broader magnetite bearing gabbro target zone – currently demonstrated through drilling and magnetics as shown in Figures 1 & 3.

Figure 3: Manindi V-Ti-Fe Project – X section showing position of holes referenced in overview along with mineralised intervals and grades

Manindi Lithium Project

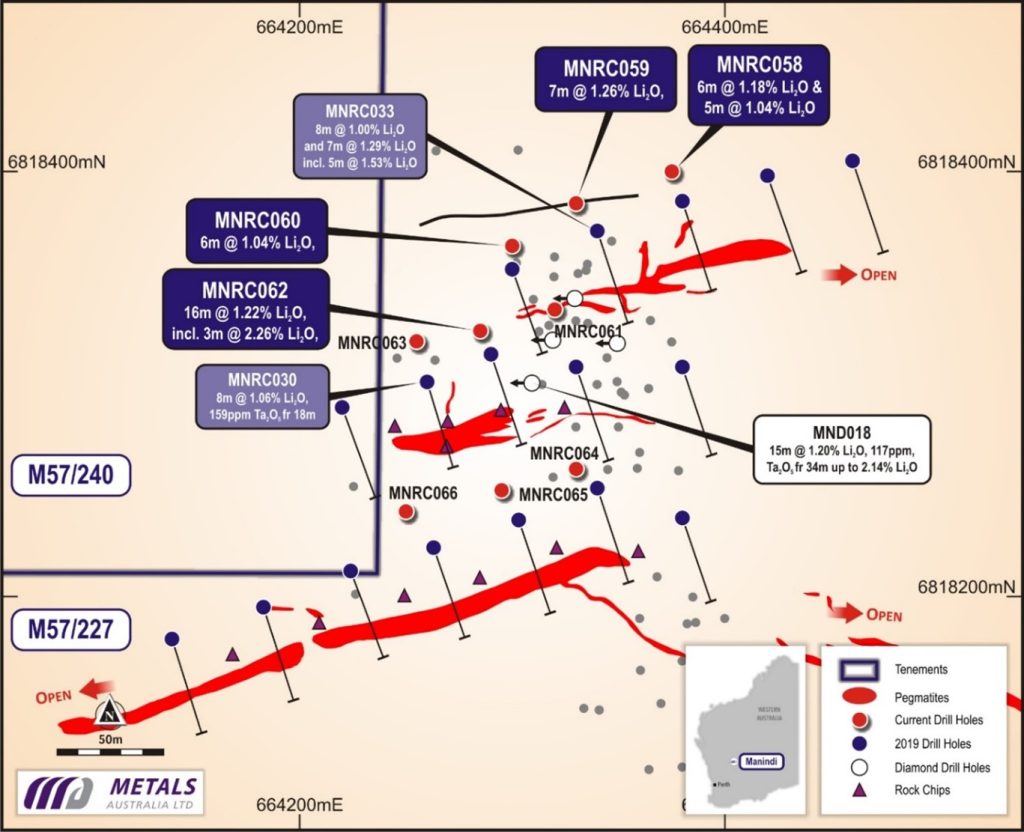

The Company has identified a corridor of lithium-bearing pegmatite occurrences over a three kilometres strike length at the northwestern end of its Manindi Project (see Figure 1 above).

Detailed surface mapping carried out at Mulgara and Warabi, situated approximately 1.3km SE of the Kultarr and Kowari zinc resources (Figure 1), previously identified at least three lithium bearing pegmatites outcropping at surface with strike lengths of over 300m and widths of up to 25-30m.

Significant intersections produced from an RC drilling program at Mulgara included: 8m @ 1.06% Li2O from 18m incl. 3m @ 1.65% Li2O with up to 1.96% Li2O in MNRC030.

Figure 4: Mulgara LCT pegmatites with rockchip and recent/previous drill hole locations

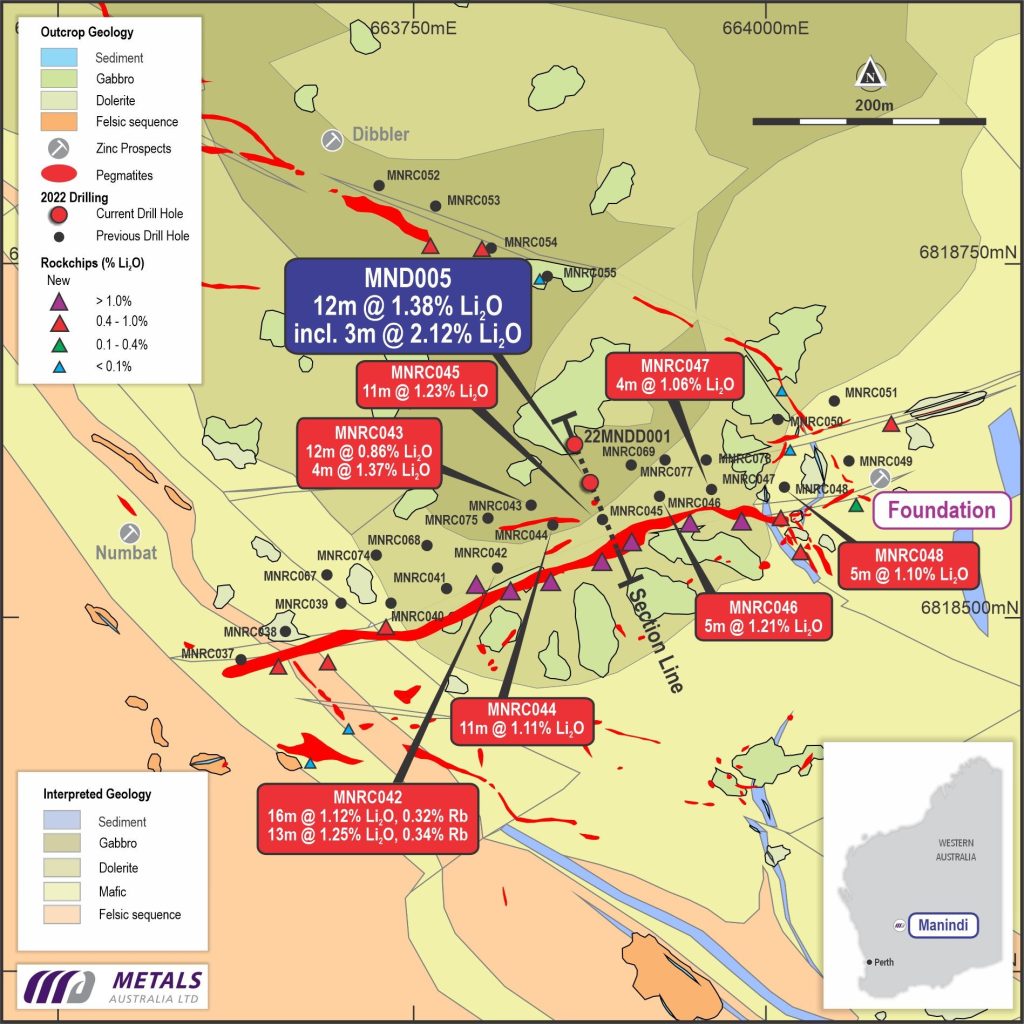

During 2022 the Company completed a 44 hole, 3,500m, RC drilling program that tested the Foundation and Mulgara Pegmatites (Figures 4) as well as other nearby zones (e.g., Dibbler, Quoll and Bandicoot. Thick and high-grade lithium-rubidium intersections have been produced from the Foundation and Mulgara pegmatites, including:

- Foundation: 16m @ 1.12% Li2O, 0.32% Rb incl. 13.0m @ 1.25% Li2O, 0.34% Rb in MNRC042

- Mulgara: 11m @ 1.23% Li2O, 0.31% Rb incl. 5m @ 1.47% Li2O, 0.30% Rb in MNRC062

In 2023 the Company announced a high-grade lithium pegmatite diamond drilling intersection from the Foundation Pegmatite (see Figure 5). The diamond hole intersected a 12.5m approximately true-width zone of steeply dipping pegmatite with visible lepidolite and petalite crystals throughout, producing a 12m intersection grading 1.38% Li2O including 3m @ 2.12% Li2O.

Figure 5: Manindi Project, Foundation Pegmatite, drilling and rockchip results

A metallurgical testwork program was undertaken utilising more than 40kg drill-core bulk sample from MND005 grading 1.33% Li2O. In 2024, the Company completed test work to produce a largely lepidolite and petalite concentrate. Initial test work proved that the lepidolite was easily able to be separated through conventional floatation, while petalite predominantly reported to the tails stream.

A follow up test program was designed and completed to separate the petalite using heavy liquid. The test work was successful, however the petalite contained a higher proportion of Fe contaminant than is permissible for use in glass or ceramics applications. It is anticipated that further processing steps to increase liberation of the Fe and then magnetic separation step would enable the petalite product to be able to meet required product specifications, however these were assessed as a costly additional step, when considering the current commodity pricing

The Company has decided to pause further work on the project until there is a material improvement in commodity pricing.